Upgrade Industrial Ethernet Port Density and Reliability with ix Industrial Connectors

Contributed By DigiKey's North American Editors

2024-02-15

Factories are experiencing a surge in data-intensive applications such as robotics, machine vision, and Industrial Internet of Things (IIoT) techniques. The result is an increasing demand for high-speed communications. While Industrial Ethernet has helped, designers must enable high port density, minimize electromagnetic interference (EMI), and ensure physically rugged connections.

At just a quarter the size of an RJ45 connector and with enhanced EMI shielding and robust mating, the ix Industrial connector was explicitly created to address factory automation requirements. Standardized under IEC 61076-3-124, the connector enables a multi-vendor range of solutions and offers a suite of nuanced features to further enhance smart factory capabilities.

This article briefly reviews factory automation connectivity requirements. It then introduces ix Industrial connectors from Hirose and shows how they can be used to meet the requirements.

Industrial Ethernet and the challenges of RJ45 connectors

Industrial Ethernet has two key characteristics that suit smart factories: a data rate of 10 gigabits per second (10 Gbps) and a technological foundation in Ethernet. It uses the same TCP/IP protocol, CAT5e and CAT6 cables, and RJ45 connectors. This interoperability makes integrating smart factory devices with each other and enterprise systems easier.

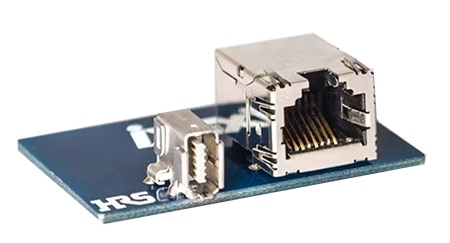

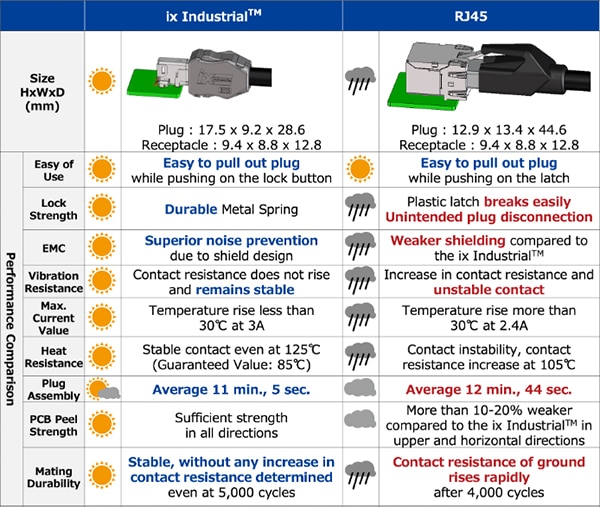

However, the industrial environment places greater physical stress on connectors, and with increasing port densities, designers need smaller footprint connectors that can also further minimize EMI. As shown in Figure 1, the ix Industrial connector reduces installation space by 75% compared to RJ45 connectors. At the same time, it offers considerably improved durability and EMI resistance (Figure 2).

Figure 1: The ix Industrial connector (left) is 75% smaller than the traditional RJ45 (right). (Image source: Automation World)

Figure 1: The ix Industrial connector (left) is 75% smaller than the traditional RJ45 (right). (Image source: Automation World)

Figure 2: ix Industrial connectors offer many performance enhancements to address factory automation requirements. (Image source: Hirose)

Figure 2: ix Industrial connectors offer many performance enhancements to address factory automation requirements. (Image source: Hirose)

Although ix Industrial uses a unique connector, it is otherwise compatible with the rest of the industrial Ethernet ecosystem. For example, it supports CAT6A cables up to 10 Gbps and power over Ethernet (PoE) and PoE+ up to 3 amperes (A).

Building on this compatibility, the miniaturized connector has been standardized under IEC 61076-3-124, ensuring cross-vendor interoperability that simplifies the design process and gives engineers greater freedom when choosing products. For example, Hirose’s ix Industrial connector series is fully compatible with solutions from other manufacturers.

The ix Industrial connector has also been selected for multiple Ethernet protocols, including PROFINET, CC-Link IE TSN, and GigE Vision:

- PROFINET is a widely used industrial Ethernet protocol overseen by Profibus and Profinet International (PI). It is used for programmable logic controllers (PLCs), robots, drives, and sensor and actuator input and output (I/O).

- CC-Link IE TSN is a standard from the CC-Link Partner Association that combines gigabit Ethernet with Time-Sensitive Networking (TSN). It is found in advanced industries such as semiconductor and automotive manufacturing.

- GigE Vision is an interface standard for high-performance industrial cameras managed by the Automated Image Association (AIA). It uses Ethernet networks to achieve benefits such as fast data transfer, extended cable length, low cost, and scalability.

In addition to these official recognitions, ix Industrial connectors can be used with many other industrial Ethernet protocols, including EtherCAT, Modbus TCP, and Ethernet/IP. With its support for these protocols and its rugged miniaturization, ix Industrial connectors are a compelling choice for many smart factory applications. These include:

- Machine vision: High-resolution cameras generate large amounts of image data for real-time analysis and decision making. This takes advantage of the ix Industrial connector’s high data rate and compact size for multi-camera setups.

- Robotics: Collaborative and autonomous robots rely on real-time sensor data and control signals for safe and efficient operation. The ix Industrial connector’s ruggedness and low EMI susceptibility ensure reliable data exchange.

- Predictive maintenance: Adding sensors to critical equipment allows for early detection of potential failures, preventing costly downtime. The ix Industrial connector’s low profile and robust design make it an excellent match for small sensors in harsh operating conditions.

Space-saving design options on plugs and receptacles

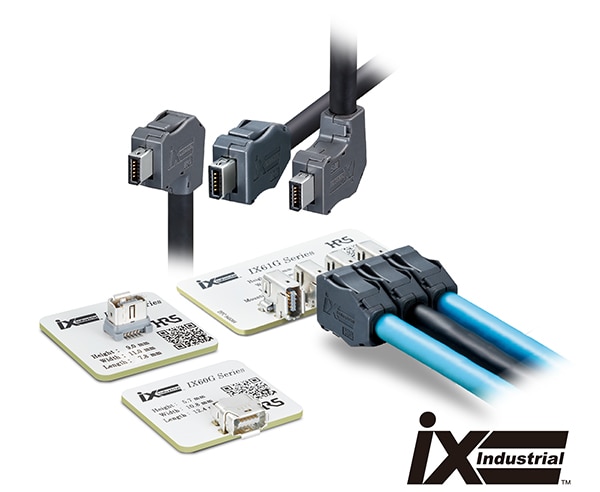

Both ix Industrial receptacles and plugs have noteworthy features that enhance space savings. As illustrated in Figure 3, the receptacles are available in a variety of configurations:

- Upright receptacles, such as the IX61G-A-10P, can be mounted in parallel with a pitch distance of only 10 millimeters (mm) for high port densities. In this configuration, six ix Industrial connectors can fit into the same space as three RJ45 connectors, significantly reducing the footprint of switches, routers, and similar equipment.

- Low-profile horizontal receptacles, such as the IX60G-A-10P, have a profile of 5.7 mm, which is less than half the height of an RJ45 connector, making them suited to applications such as sensors.

- Vertical receptacles, such as the IX80G-A-10P, can be mated from the top, giving designers added flexibility.

Figure 3: ix Industrial receptacles are available in upright, vertical, and horizontal variants (top, left, and bottom, respectively). The plug connectors come in straight and right-angle configurations. (Image source: Hirose)

Figure 3: ix Industrial receptacles are available in upright, vertical, and horizontal variants (top, left, and bottom, respectively). The plug connectors come in straight and right-angle configurations. (Image source: Hirose)

The plugs are available in either a straight orientation, such as the IX40G-B-10S-CV(7.0), or a right-angle orientation, such as the IX30G-A-10S-CVL2(7.0). The right-angle options are particularly noteworthy, as they reduce the height of the connection and make it easier to route the cable in tight spaces. For example, these plugs can minimize issues related to cable bend radius and facilitate high-density daisy chaining.

Mechanical and electrical resilience

Designed to withstand industrial conditions, the ix Industrial connector features a rugged construction resistant to vibration, impact, and EMI. The receptacle shell is mounted to the printed circuit board (pc board) via five through-hole solder legs. This creates a solid physical connection that resists wrenching and pulling, protecting the signal contacts. It also supplies a robust connection between the receptacle shell and the board’s ground plane.

The plug shell comprises an integrated wire-termination unit and cable clamp (Figure 4). This prevents the connecting part of the cable assembly from being affected by the load on the cable. The shell is crimped together and comes into direct contact with the receptacle’s ground spring, creating a continuous 360˚ shield against EMI.

Figure 4: The ix Industrial plug encases the wire-termination unit with a shell that protects against physical damage and EMI. (Image source: Hirose)

Figure 4: The ix Industrial plug encases the wire-termination unit with a shell that protects against physical damage and EMI. (Image source: Hirose)

The connectors also feature a robust snap-in locking mechanism that provides an audible and tactile click. This positive lock mechanism ensures a secure connection even in environments with heavy vibrations and helps the connector withstand 5,000 mating cycles.

Hirose also offers variants of its ix Industrial connectors with palladium-nickel contacts. For example, the IX30G-A-10S-CV(7.0)(01) plug uses contacts with 0.75 micrometers (μm) of palladium-nickel plus 0.05 μm of gold plating. These contacts are more durable than the standard gold ones and are invaluable for applications with frequent mating cycles.

Simplifying assembly and testing

Hirose recommends using cables with wire sizes between 22 and 28 American Wire Gauge (AWG) to ensure a high-quality connection. The wires can be terminated by soldering or insulation displacement connections (IDC), with IDC recommended for field-terminated plugs. This termination method uses a crimping tool such as the HT803/IXG-8/10S-63-72 to cut through the wire insulators and connect in a single motion.

For the most durable and high-quality termination, soldering is preferred. Hirose offers numerous plugs, like the IX40G-A-10S-CV(7.0), that support this termination method.

To test cables and assemblies, Hirose offers the DSX-CHA-5-IX-S, a set of adapters for the Amprobe (a Fluke Networks company) DSX CableAnalyzer. Using this analyzer, technicians can ensure proper operation and simplify the diagnosis of any problems.

Conclusion

Designers can use ix Industrial connectors to achieve high port density and reliability in smart factory applications. With their standardization under IEC 61076-3-124, designers are assured interoperability between manufacturers. The variety of plug and receptacle options allows designers to choose mounting and cable routing orientations to shrink the footprint of their equipment, avoid cable stress, and achieve high bandwidth with minimal risk of interference.

Recommended Reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.